Recently, some repair technicians have come across the unresponsive/malfunction 3D touch on some of the “OEM” iPhone 6S/6S+ screen assemblies. We ETS have done several researches to find out the reasons behind this issue.

1. How 3D Touch Works?

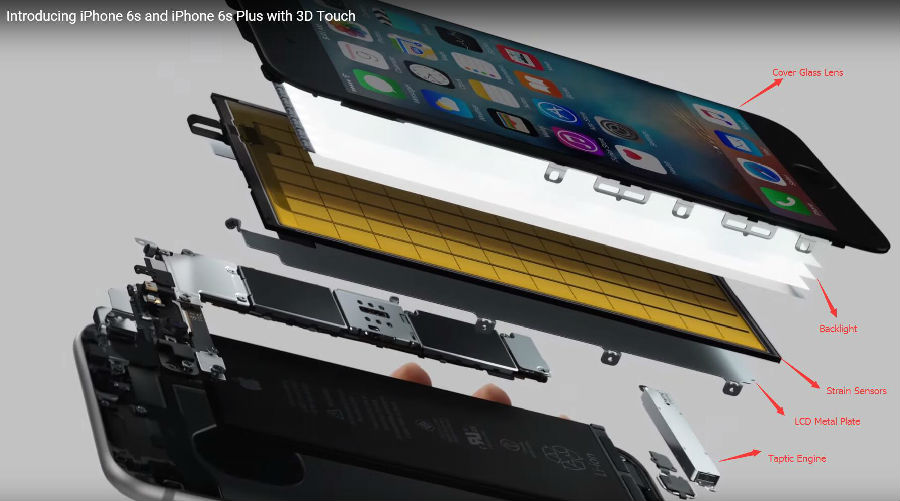

3D Touch is the main updating feature of iPhone 6S/6S+, which brought a brand new user interaction way to the phone. Before, users can only interact with the iPhone in 2 dimensions, however, for the 6S/6S+, vertical force can be sensed & calculated, and different feedback will be shown up. Below are two main components which contribute to the 3D touch function:

a. Strain Sensor

Right under the LCD backlight, are the 8X12 strain sensors. When the users press down the cover glass lens, there would be slightly deformation of the glass, which will shorten the distance between the glass and the strain sensors behind. When one strain sensor receives the signal that the distance in between has been changed, the system will compare the signal received nearby to calculate where the touch happened and how much strength the user used, then to recognize it as “Peek” or “Pop”.

b. Taptic Engine

The new Taptic Engine is designed for a better response to the vertical force touch. If the touch is recognized as “Peek”, the Taptic Engine will make a 10 millisecond “Minitap”; if the touch is recognized as “Pop”, the Taptic Engine will make a 15 millisecond “Fulltap”, which makes the user feel like a real touch.

The Inner Structure of 6S/6S+:

How 3D Touch Works:

2. Possible Reasons Why This Issue Happened.

Now in the market, there are two kinds of screen assemblies. One is OEM screen assembly, the other one is screen assembly which made of OEM materials but assembled by the third party factories. After tests, 9/10 screen assemblies which assembled by the third party factories are experiencing malfunctioning 3D touch function.

a. First we thought the problem may be happened in the 3D touch layer (strain sensors), whether because it may not be OEM or because of the way it was assembled. However, after transferring the 3D touch layer which we disassembled from the third party factories to the OEM screen assembly, we found the 3D Touch functions as usual without any problems; however, the OEM 3D touch layer cannot solve the malfunctioning screen assemblies assembled by third party factories.

b. The reasons should be the way how screen assembly been assembled. Then we disassembled the screen assembly into pieces to find out. After measurements, the thickness of third party assembled screen assembly is 1.59mm, while the OEM one is 1.50mm.

The cover glass lens of both these two screen assemblies are 0.84mm.

As there are no copied LCDs available for 6S/6S+ yet, how could the difference in thickness from?

The answer is the adhesive. For OEM screen assemblies, the manufacturers uses OCA (Optical Clear Adhesive), while for third party factories assembled one, in order to cut the cost to make more profits, they have adopted LOCA (Liquid Optical Clear Adhesive) glue instead of OCA.

3. Why would LOCA Glue Affect the 3D Touch Function?

As we stated before, the 3D Touch function is based on the slightly deformation of the cover glass which will be detected by strain sensors through the distance change between the cover glass and the sensors. However, LOCA glue is not solid, which means if you press down the screen, some of the glue behind will be squeezed nearby which will affect the detection of the distance. This will cause the malfunction of the 3D Touch function.

Conclusion:

As far as we know, all third party assembled 6S/6S+ screens have used LOCA to bond the glass currently. We do recommend you buy OEM 6S/6S+ screen assemblies at the moment. Once there are assembled screens using OCA glue which can pass the QC tests, third party assembled screen will be a choice for you. If you are in the screen refurbishing business, don't use LOCA for 6S/6S+ screen refurbishing.

Share this guide with your friend!

Download and print the report here!

Loading...

Loading...