Sony Official Reveals the Waterproof Cellphone Repair Process

BY yuki | 九月 13th, 2013 | 77 | 7

Since Sony Mobile was established in 2012, it has launched several waterproof and dustproof smartphones, such as Sony Xperia Z, Xperia ZR and Xperia Z Ultra. These Sony handsets adopt high-standard water-resistant certification, especially for the Sony Xperia Z Ultra, which has passed IP58 certified with water resistant over 1 meter under water. These high-end devices feature strong waterproof function. If they are water-damaged and need to be repaired, how to check if the waterproof function is invalid or how to get it repaired well without voiding the waterproof performance?

Thanks to the detailed demonstration from Sony Mobile repair headquarters in Taiwan, the secret of water-resistant smartphone repair process is unveiled. When the Sony Mobile repair departments receive water-damaged waterproof phones needed to repair, they will distinguish the damage elements to see if the problems are caused by people’s improper usage. They will go through three inspection processes: "check damp sticker", "test water tightness" and "disassemble phone to inspect oxidation traces".

1. Check the damp sticker

This is the basic step to check if the smartphone gets wet. Sony waterproof cellphones are designed with pieces of damp stickers. When you open the cover of the waterproof hole, you will see the damp paper. If the damp paper color has changed, your smartphone is wet.

2. Test air tightness pressure view

The airtightness test is helpful to detect whether the smartphone waterproof function is intact. The phone is connected to the test equipment with a clip.

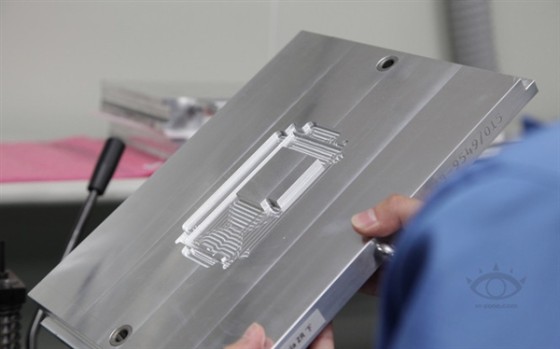

The air tightness test situation displays on the computer. It shows the condition of pumping out the air.

If the airtightness is sound, it means the water tightness of the cellphone performs well. The test is passed.

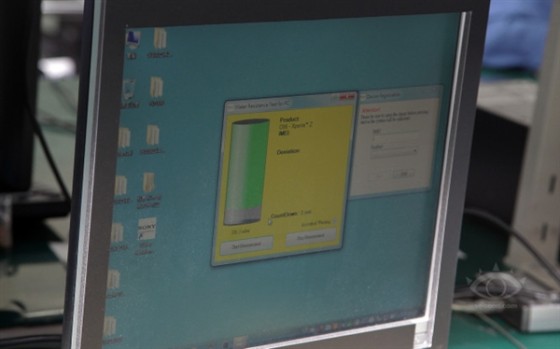

If the phone does not pass the airtightness test, the computer will show the red surface.

Sony waterproof smartphone is designed with a water-resistant test hole, which is used to test the water tightness by instrument. In the condition of the waterproof hole closed, if the wet cellphones have passed the air tightness test, but the damp sticker is in discoloration, or the phone board is wet, the wet phone problem may be caused by human factor.

3. Disassemble the phone to view

The maintenance personnel would disassemble the phone with the help of sophisticated instruments to inspect the flow path and water oxidation trace on the phone board.

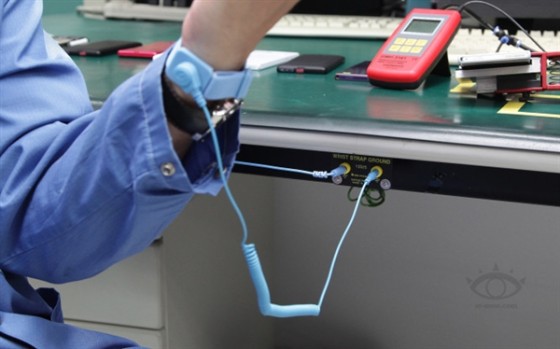

The whole repair process should proceed in the environment of a static state in order to prevent from dust contamination. Therefore, the repair workers should wear anti-static clothing as well as anti-static wrist strap to make sure the repair process in a normal waterproof state without any dust.

All relevant operators should be in a static condition during the inspecting and maintenance process.

All Sony headquarter, factory or Taiwanese maintenance center provide professional cellphone maintenance workbench, which can make technicians carry on disassembly without destroying the waterproof performance. Through the above waterproof inspecting process, if the professional workers confirm the Sony mobile phone are damaged by water, they will disassemble the wet phone to repair it. The entire process will be recorded by camera. And the relevant data, reports, pictures or videos will keep in archives.

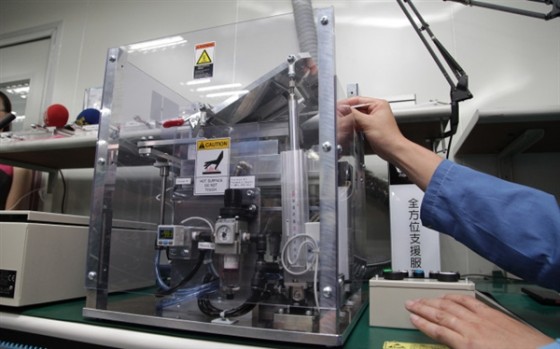

These waterproof phones are dedicated devices and the LCD screen and digitizer touch screen are tightly assembled to achieve ultra-thin outlook. To repair the phone, maintenance technicians should carry on the disassembly and assembly by using precise dismantling equipment.

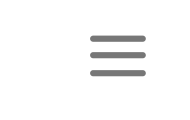

This is the Sophisticated dismantling equipment in Taiwanese workbench. The instrument can soften the double-sided adhesive between the LCD screen and the housing with hot temperature.

When separating the LCD screen, the professional dismantling instrument will not damage the screen and the waterproof performance.

In short time, the Sony cellphone screen is successfully disassembled.

The repair technicians should remove the flex cable ribbon carefully, for the ribbon cable is frangible.

Taking out the LCD screens and housing parts from the instrument. Both the Sony mobile phone LCD screen and the board are separated.

After the dismantling is completed, maintenance operators should reassemble the cellphone with the brand-new waterproof tape.

The tap should be carefully attached to the board with specific pressure.

Under normal circumstance, the technicians will test the cellphone's airtightness before disassembling and assembling, following the factory production procedure. All these operations aim at ensuring the 100% waterproof performance. At the final seal assembly stage, Sony waterproof Xperia series need to go through different pressures test in order to provide the most excellent waterproof state. This test process is the same as the factory's, and kept track by specific workers to guarantee the normal waterproof capability.

Connecting the screen flex cable ribbon.

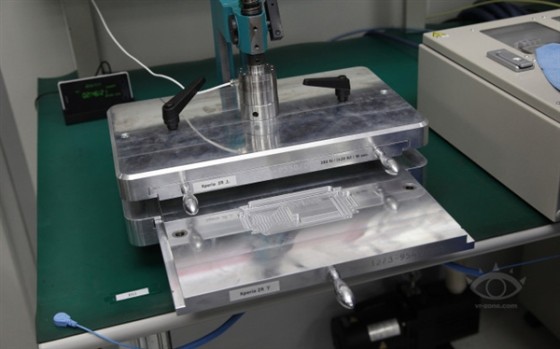

Do the encapsulation with special mold tool

The sophisticated instrument is used to assemble the cellphone screen.

Place the smartphone parts in the metal plates, and then put it in the lamination device, the phone is compressed to ultra-slim appearance with waterproof performance.

According to Sony customer service department, the most common reasons for the failures of waterproof performance lie in the unclosed waterproof hole. In this condition, cellphone gets wet, but it can pass the airtight test by instrument. As for the discoloration damp paper, it does not mean the cellphone gets wet. It may be caused by the moisture in the air or suffer water from the hole cover. Therefore, when users intend to use waterproof cellphone under water, please check if the waterproof airtightness hole is closed completely.